GoliathTech New England

New Technology for an Age-Old Problem

By CHL Staff

The strength, durability, and integrity of any structure building above the ground are in the foundation it rests on. The design of the foundation should bear the load-bearing load above it. Under any type of soil conditions and colder climates, the depth of frost will vary. The single most important factor in building any structure, including decks, additions, docks, and raised structures is soil conditions. Throughout the country in all regions, soil conditions vary from compacted dirt, to till, clay, ledge, rock, loose sand, and particulates as well as combinations of all of the above. The secret to successful building projects of any kind is to get it right the first time, and with foundations, there are no second chances. Any failure after building results in cost often 2-3 times the original investment to correct structural issues.

One of the most innovating and newest technologies in foundations and footings for the building of all kinds is screw piles. The technology has been around since the mid-1800s and had stood the test of time and durability with all types of soil applications and weather conditions. The first screw-pile supporting structures were lighthouses. These were buildings by blind Irish engineer Alexander Mitchell in 1838 at the mouth of the Thames River in Southern England. The innovative method of using screw piles that sink deep into sandy river bottoms is providing a solid structural base for these lighthouses. They are still operating today. In the United States, several screw-pile lighthouses were built in the Chesapeake Bay due to its estuarine soft bottom. Mainly in the Sound and River Inlet of North Carolina and the Southeast, including Florida and its many major attractions.

Transforming Age-Old Technology

GoliathTech has taken an age-old technology and transformed it into a simple and reliable solution for building foundations and footings in any region, any soil condition, at any time of year. Their process is flexible, reliable and offers a quick and simple solution to an age-old problem that is a guarantee for 50 years.

Screw-piles and helical anchors are unique among most other types of foundations or anchoring systems. Because they are so unique, they can load immediately after installation. There is no need to wait for concrete or grout to harden. Or in the case of piling. No need to wait for excess pore water pressures to dissipate. Under almost all soil conditions, the ultimate bearing capacity of screw piles and screw anchors will increase over time due to aging and thixotropy. This issue means that the capacity for load increases over time as the foundation footings age.

New Economical Process

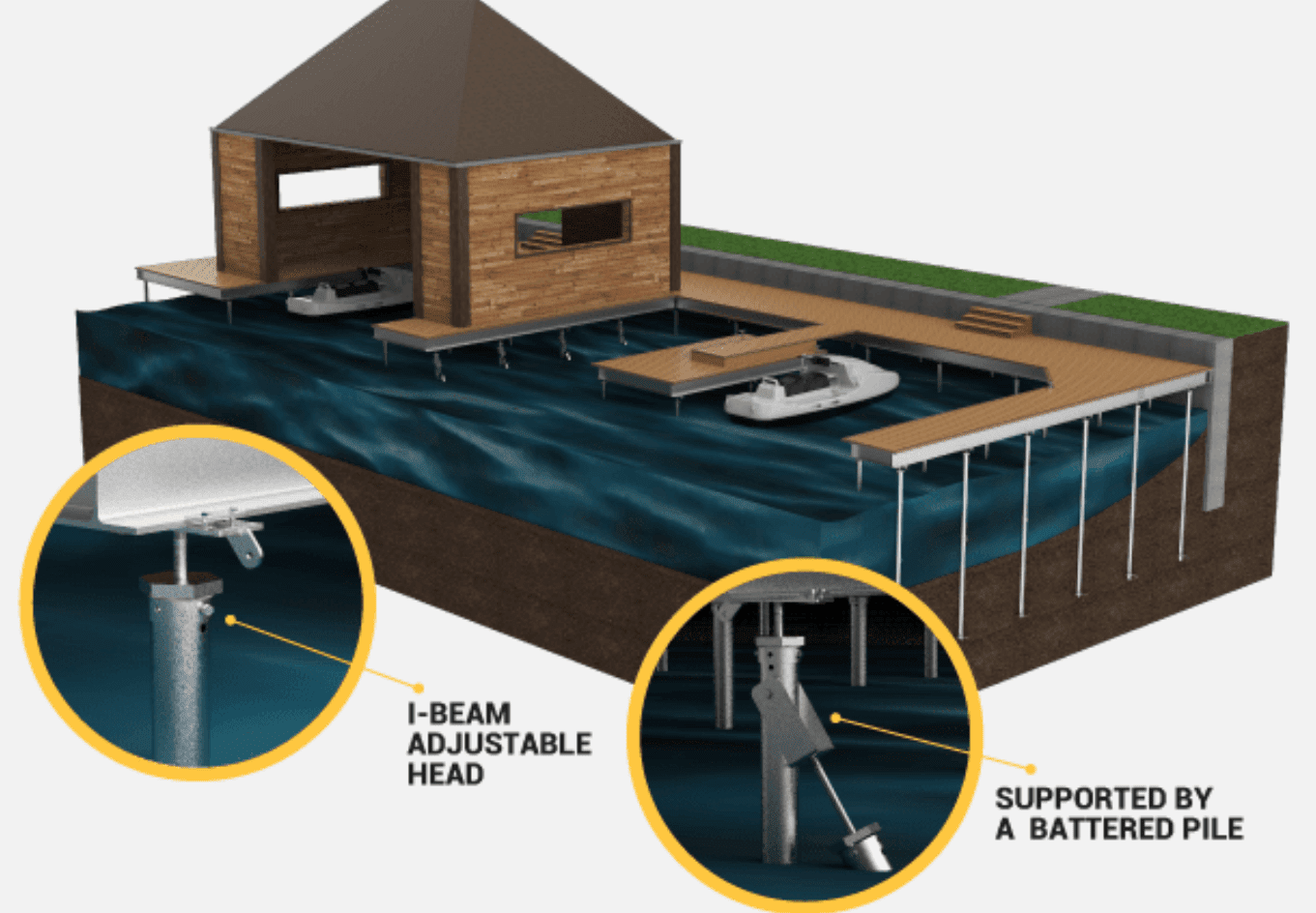

Helical Piles are a deep foundation solution that allows for construction in weak soil types and in limited access sites. They are familiar for their lack of noise and limiting ground disturbance. The benefit of using Helical Piles is that companies are able to get to the correct depth. This idea leads to a much more economical process. With a crew of four, the foundation can set in hours instead of days. There is an ongoing drive to lower production costs. Therefore, for this reason, spiral anchors are becoming more and more popular in deep foundation work worldwide. They have become the leading application for engineers and architects.

Jeff O’Rourke from GoliathTech explained,” This process has created an entirely new opportunity to quickly install stable foundations, footings, fencing, docks & deck support systems in any soil conditions including water with minimal site disturbance in any weather condition. We can provide a stronger, more reliable, and longer-lasting solution for structures of all kinds. With this, they will stand the test of time and perform in any application. Getting the task done quickly with no heavy equipment, site interruption, and digging makes this game-changing.”

On your next project contact the pro’s at GoliathTech for building and construction foundation solutions at goliathtechpiles.com or 978.362.8900